Floveyor, the aeromechanical conveyor

The aeromechanical conveyor is the evolution and all-purpose weapon in the conveying of bulk materials. With the more efficient alternative to the classic chain conveyor, all common free-flowing bulk materials (from fine powders to granulates) are conveyed in high throughputs and with almost no wear. With its slim design, it conveys your products both from, or into, silos, BigBags, mixers, packaging machines and much more

Due to its unique properties, aeromechanical conveying is also ideally suited as a replacement for bucket elevators in the area of powdery bulk materials.

The Aeromechanical Principle

The conveyor cable moves through a tube at a speed of 4m/s, creating suction/vacuum behind the conveyor disc. The material – any free-flowing bulk material is suitable – is “pulled” or sucked into this suction without almost no frictional forces or wear on the bulk material.

When operating without material, only the existing conveying air circulates in the pipes. When the product is fed, the product volume displaces the air volume. When ejecting, the same amount of air is sucked in again via the funnel.

Advantages

- Very high flow rates with minimum maintenance

- Minimum stress on the bulk material

- low energy costs due to 1.5 kW drive

- Conveying at any angle, from horizontal to vertical.

- Can be used as a fixed installation or mobile

- Dry and wet cleaning possible

- No external dosing necessary for product feed

- ATEX Zone II 2D Ex IIIB T200°C Db

Funktionsgalerie

Individualization

By arrangement, the machine can be adapted to any requirement of your processing procedures and sequences. A small overview of the possible extensions:

- Bag or BigBag task

- Chassis for mobile operations on-site

- Winch for changing the conveying angle

- Wet and dry cleaning

- Direct flange for screw conveyors etc.

- Distributor valves

- Lump crushers

- Magnets

- Multiple deflections

- Adaptation to ATEX directives

Systems and possible applications

Tanker loading by Floveyor

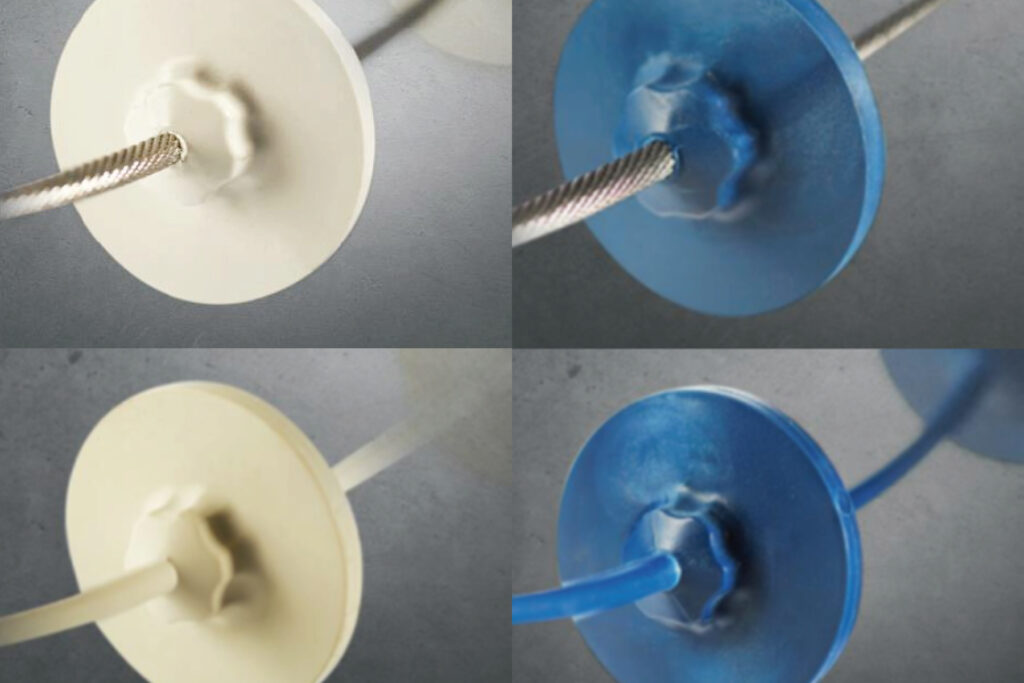

Sheathed ropes in polymer coating

The great advantage of this design, which has been tried and tested in practice since 2005, is that the transport sheaves and the cable are fused in a single operation, completely without rivets. This results in a complete seal between the two assemblies, an optimum prerequisite for a particularly long service life and clean operation.

Can also be used for other makes

Conveyor cables are available in AISI 304 and AISI 329 (magnetic) stainless steel, bare or sheathed in white and blue PU (optional magnetic).

Conveyor discs made of PU are available in white or blue and optionally magnetic.

Questions and answers

What advantages does Floveyor offer to the tube chain conveyor?

- Significantly reduced wear on both product and machine.

- The product is only minimally stressed.

- Higher throughput with smaller conveying tubes

- Product changeover is faster and easier.

What advantages does Floveyor offer over pneumatic conveyors?

What are the advantages of Floveyor over bucket elevators?

How flexible is the aeromechanical principle?

Optionally, a mobile chassis can be mounted, allowing the Floveyor machines to be moved manually.

Each machine is adapted to the conditions on-site or the connected process units.

Which products can be conveyed aeromechanically?

What do I need to take into account when changing products?

Dry cleaning is possible during the running process.

Wet cleaning also not a problem

What conveyor cable variants are there?

The ropes are available in three materials or designs:

- Bare AISI 304, AISI 329 stainless steel, magnetic

- sheathed in PU, white and blue

- sheated in PU, magnetic

The cast-on conveyor discs are available in

- PU in white or blue

- Magnetically detectable PU in blue

- We only offer riveted discs on express request

Does the product have to be fed in doses?

How much maintenance is required?

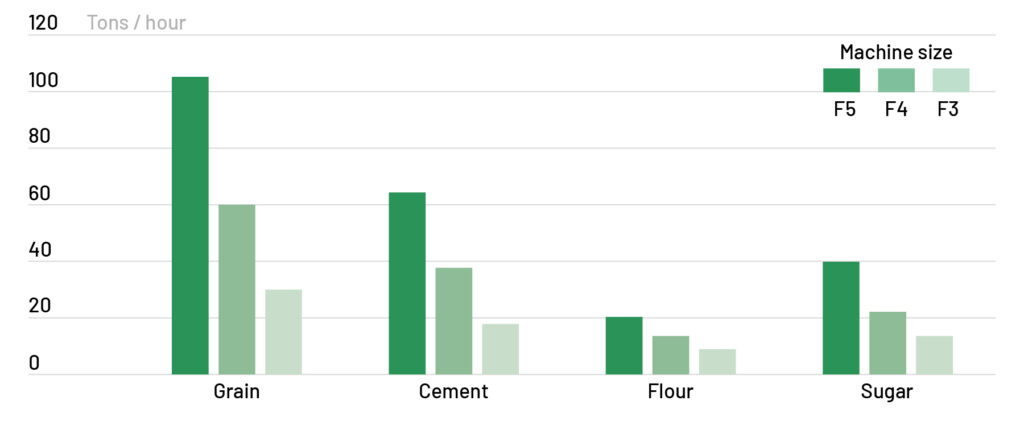

What is the capacity of the machine?

CONTACT

Would you like more information or to contact us personally?

Write to us.

We look forward to hearing from you.